However, the variance between actual overhead and estimated will be reconciled and adjust to the financial statement. Notice that the formula of predetermined overhead rate is entirely based on estimates. The overhead applied to products or job orders would, therefore, be different from the actual overhead incurred by jobs or products.

Multiple or departmental predetermined overhead rates:

As a result, there is cash flow a high probability that the actual overheads incurred could turn out to be way different than the estimate. Various tools help in calculating and applying predetermined overhead rates effectively. The most prominent concern of this rate is that it is not realistic being that it is based on estimates.

- They enable businesses to compare actual overhead costs with the estimated rates, identify variances, and take corrective actions if necessary.

- Take, for instance, a manufacturing company that produces gadgets; the production process of the gadgets would require raw material inputs and direct labor.

- A later analysis reveals that the actual amount that should have been assigned to inventory is $48,000, so the $2,000 difference is charged to the cost of goods sold.

- In a company, the management wants to calculate the predetermined overhead to set aside some amount for the allocation of a cost unit.

- Hence, one of the major advantages of predetermined overhead rate formula is that it is useful in price setting.

Predetermined Overhead Rate Formula

Their amount of allocated overhead is not publicly known because while publications share how much money a movie has produced in ticket sales, it is rare that the actual expenses are released to the public. Therefore, this predetermined overhead rate of 250 is used in the pricing of the new product. Hence, preliminary, company A could be the winner of the auction even though the labor hour used by company B is less, and units produced more only because its overhead rate is more than that of company A. After reviewing the product cost and consulting with the marketing department, the sales prices were set. The sales price, cost of each product, and resulting gross profit are shown in Figure 6.6. Two companies, ABC company, and XYZ predetermined overhead rate company are competing to get a massive order that will make them much recognized in the market.

- As a result, management would likely view labor hours as the activity base when applying overhead costs.

- Therefore, this predetermined overhead rate of 250 is used in the pricing of the new product.

- For example, the recipe for shea butter has easily identifiable quantities of shea nuts and other ingredients.

- The elimination of difference between applied overhead and actual overhead is known as “disposition of over or under-applied overhead”.

- Further, it is stated that the reason for the same is that overhead is based on estimations and not the actuals.

Monitoring relative expenses

- Companies need to make certain the sales price is higher than the prime costs and the overhead costs.

- With 150,000 units, the direct material cost is $525,000; the direct labor cost is $1,500,000; and the manufacturing overhead applied is $750,000 for a total Cost of Goods Sold of $2,775,000.

- This comparison can be used to monitor or predict expenses for the next project (or fiscal year).

- Based on the manufacturing process, it is also easy to determine the direct labor cost.

- Often, the actual overhead costs experienced in the coming period are higher or lower than those budgeted when the estimated overhead rate or rates were determined.

- Manufacturing overhead costs include all manufacturing costs except for direct materials and direct labor.

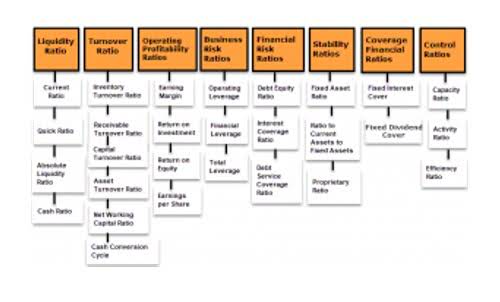

According to a survey 34% of the manufacturing businesses use a single plant wide overhead rate, 44% use multiple overhead rates and rest of the companies use activity based costing (ABC) system. A large organization uses multiple predetermined overhead recovery rates to allocate its expenses to the cost centers. However, small organizations with small budgets cannot afford to have multiple predetermined overhead allocation mechanisms since it requires experts to determine the same.

- This can help to keep costs in check and to know when to cut back on spending in order to stay on budget.

- The company, having calculated its overhead costs as $20 per labor hour, now has a baseline cost-per-hour figure that it can use to appropriately charge its customers for labor and earn a profit.

- For example, assume a company expects its total manufacturing costs to amount to $400,000 in the coming period and the company expects the staff to work a total of 20,000 direct labor hours.

- This is because using this rate allows them to avoid compiling actual overhead costs as part of their closing process.

- Implementing predetermined overhead rates involves key steps for accurate cost allocation.

- Before the beginning of any accounting year, it is determined to estimate the level of activity and the amount of overhead required to allocate the same.

Examples can include labor hours incurred, labor costs paid, amounts of materials used in production, units produced, or any other activity that has a cause-and-effect relationship with incurred costs. Catch Up Bookkeeping Hence, it is essential to use rates that determine how much of the overhead costs are applied to each unit of production output. This is why a predetermined overhead rate is computed to allocate the overhead costs to the production output in order to determine a cost for a product. The predetermined overhead rate is, therefore, usually used for contract bidding, product pricing, and allocation of resources within a company, based on each department’s utilization of resources. In a company, the management wants to calculate the predetermined overhead to set aside some amount for the allocation of a cost unit. A number of possible allocation bases are available for the denominator, such as direct labor hours, direct labor dollars, and machine hours.

C. Financial Reporting

Nonetheless, ignoring overhead costs, like utilities, rent, and administrative expenses that indirectly contribute to the production process of these gadgets, would result in underestimating the cost of each gadget. As the production head wants to calculate the predetermined overhead rate, all the direct costs will be ignored, whether direct cost (labor or material). Larger organizations may employ a different predetermined overhead rate in each production department, which tends to improve the accuracy of overhead application by employing a higher level of precision. However, the use of multiple predetermined overhead rates also increases the amount of required accounting labor. In these situations, a direct cost (labor) has been replaced by an overhead cost (e.g., depreciation on equipment). Because of this decrease in reliance on labor and/or changes in the types of production complexity and methods, the traditional method of overhead allocation becomes less effective in certain production environments.